The sixth ITMA Asia + CITME in Shanghai, China, was extremely successful for Groz-Beckert. Over the five days of the trade fair in October 2018, the company welcomed over 4,000 international customers and partners to its booth. Around three quarters of the customers at the Groz-Beckert booth came from China, followed by guests from Japan, India and South Korea.

With its 1,733 exhibitors from 28 countries, the trade fair attracted more than 100,000 visitors in total. These visitors were treated to a wide range of state-of-the-art technology for manufacturing and joining textile fabrics. Groz-Beckert was represented with all six product areas – Knitting, Weaving, Felting, Tufting, Carding and Sewing – and presented new transparent insights at its booth in Hall 4, Booth D25.

WeChat Channel is Online for Chinese Market

The still relatively recent WeChat Channel also put the company in the spotlight. Visitors had the opportunity to become a follower directly at the booth and to receive the latest news on Groz-Beckert and the Chinese textile market on their smartphone in the future. In order to establish optimal communication in the Chinese market, the Groz-Beckert WeChat Account went online in 2017. Since then, the needle manufacturer has been providing weekly news on the company, its products and services, as well as the latest topics relating to all aspects of the Chinese textile market. As usual on WeChat, the content is published in Chinese – the Groz-Beckert Account also includes links to content in English.

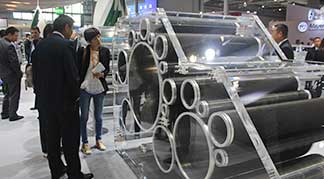

The Groz-Beckert product areas presented their product ranges using the tried-and-tested acrylic glass machines, with some new acrylic glass exhibits. In the Knitting area, for example, a new acrylic glass machine for sock production was added; while the Sewing division presented a new acrylic glass sewing machine. Knitting division placed a particular focus on a system-oriented approach: Thanks to extremely tight production tolerances, needles and system parts from a single source guarantee precisely coordinated tools for smooth interaction.

The Felting (Nonwovens) division showed its staple fiber needle punch line live in Asia – as a 3D print model in 1:18 scale. The original system is available for customers to test in the Technology and Development Center (TEZ) in Albstadt, Germany. The system is available to customers and partners for tests and joint projects.

The division also presentined its patented GEBECON® Felting Needle, which offers improved surface quality and optimal bending resistance. The EcoStar® Felting Needle is a real highlight for all applications with the highest demands for surface quality. For spunlace customers, Groz-Beckert presentined the innovative HyTec® jet strip. The significantly higher hardness and the spring-hard properties have a positive impact on all mechanical properties.

New Solutions with WeavingLoom

Using the WeavingLoom, a weaving machine replicated in acrylic glass, Groz-Beckert showed heald frames and healds; as well as warp stop motions, drop wires and the PosiLeno® leno system in action. The high-performance tying machine KnotMaster presented in the field of weaving preparation. Four fabric strips also be presented, highlighting the different applications, from leno to jacquard fabric. Illustrative hand samples of the weaving accessories harness frames and healds completed the Weaving exhibition.

Tufting showed its gauge part system; which impressed with the controlled and coordinated selection of materials and compliance with the tightest tolerances. And the Carding division also presented its clothings on two impressive acrylic glass exhibits; which showed a revolving flat card and a roller card. The use of special clothing geometries in the nonwovens industry; like the worker and doffer wires SiroLock® and EvoStep® leads to better fiber control and a more even web. The SiroLock® card clothing also impresses with increased performance of the roller card; while EvoStep® card clothing focuses on saving raw material.

The unique transparent insights at the Groz-Beckert booth impressively demonstrated the interplay between the different components in textile machines. They clearly highlight the extremely low tolerances the needles and system parts from Groz-Beckert work in.

The ITMA Asia 2018 was a complete success for Groz-Beckert with a wealth of interesting discussions and major incentives for the coming months.