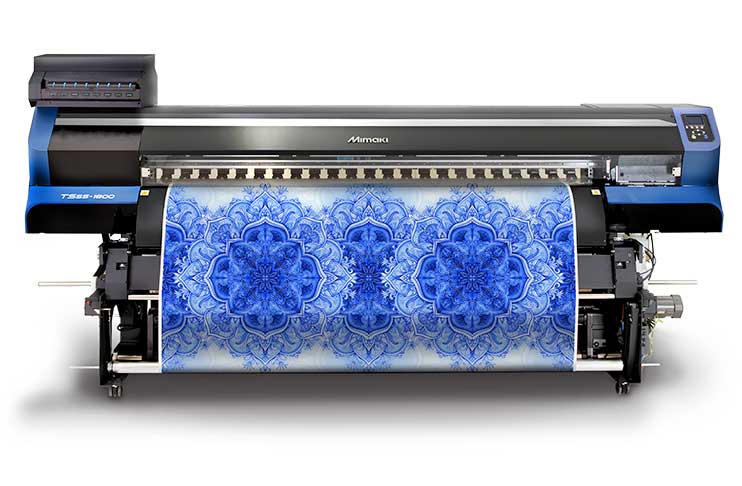

TS55-1800 makes high-end features available to everyone, including low-running costs, industry-leading productivity and reliability.

Mimaki today announced the launch of the Mimaki TS55-1800, a revolutionary new digital heat transfer sublimation printer, that brings high-end features to the entry and mid-level market. These include high-speed one-pass printing at a high-resolution and high ink-density, unattended printing with the new Mini Jumbo Roll and Mimaki’s Nozzle Check and Recovery System for continuous operation.

With the release of the TS55-1800, Mimaki delivers on making high-end digital textile printing features available to a much broader market. Now, textile professionals can effortlessly scale their operation with an affordable heat sublimation printer that meets the high quality and fast turnaround times demanded in the dynamic textile and apparel industry. The new model prints at a resolution of 480×600 dpi with a high ink density using one-pass printing at 140 sqm/h (1,506 sq.ft/h). In addition, the unique Mimaki Advanced Pass System (MAPS4) improves the quality of two-pass printing by eliminating banding. The TS55-1800 achieves all this with low running costs and the high-productivity and reliability that Mimaki products are known for.

Emphasizing the superior technical features of TS55-1800, Mimaki Eurasia General Manager Arjen Evertse said that the product will open the doors of a new era in digital textile printing. Evertse; “The unique features of our revolutionary textile machine will be introduced to the market in Sign Istanbul 2018 for the first time in the EMEA region, and TS55-1800 will cause a revival in the textile market. Designed and developed from scratch, TS55-1800 will be first choice of those who want to come forward in the competition for this segment, where competition is intense.” Evertse underlined textile manufacturers will reach the high-quality, industrial efficiency and low operational costs they look in printing with this machine.

TS55-1800 and unattended printing

One of the key features of the TS55-1800 is the optional use of new Mini Jumbo Roll unit; that can continuously feed 2,500 linear meters of heat transfer paper to the printer. This enables customers to substitute the use of Small Plotter Rolls with Mini Jumbo Rolls; which can save them over 20% in print media cost. Furthermore, Mini Jumbo Rolls of Mimaki Vision Jet-X transfer paper; supplied by Neenah Coldenhove, will be offered as package deal with the TS55-1800. The 2,500 m1 Mini Jumbo Rolls are the ideal way to upgrade to high-volume unattended textile printing. In addition, the printer is fitted with the unique Mimaki Nozzle Check and Recovery System and 10-liter ink tanks; which ensure failsafe continuous operation for extended operational periods, such as overnight-unattended printing.

Higher profitability

Mimaki offers its customers a high return on investment with the TS55-1800; that will be sold at a very competitive price-point. “It will outdistance its competitors in its segment comparing the price ratio with the quality. We offer the best specifications for the best price to the users,” said Arjen Evertse; and continued saying textile professionals can reduce their operational cost and double their annual profit by using TS55-1800. Evertse; “There will be a real revolution with the TS55-1800 in the textile industry; which has been advancing with similar technologies for many years. This is truly revolutionary; and we believe it will make a huge contribution to the analogue-to-digital transformation underway in the industry; and it will be an indispensable investment for preparing the industry for tomorrow and taking the competition forward.”