The 2025 Recycled Polyester Challenge calls on companies to commit to sourcing from 45% to 100% of their polyester from recycled sources by 2025. It aims to stop new fossil-based synthetic fibers from entering the system, rather than substitute other material categories or justify increased industry growth. In April 2021, Textile Exchange teamed up with the United Nations Framework Convention on Climate Change’s (UNFCCC) Fashion Industry Charter for Climate Action to launch the 2025 Recycled Polyester Challenge.

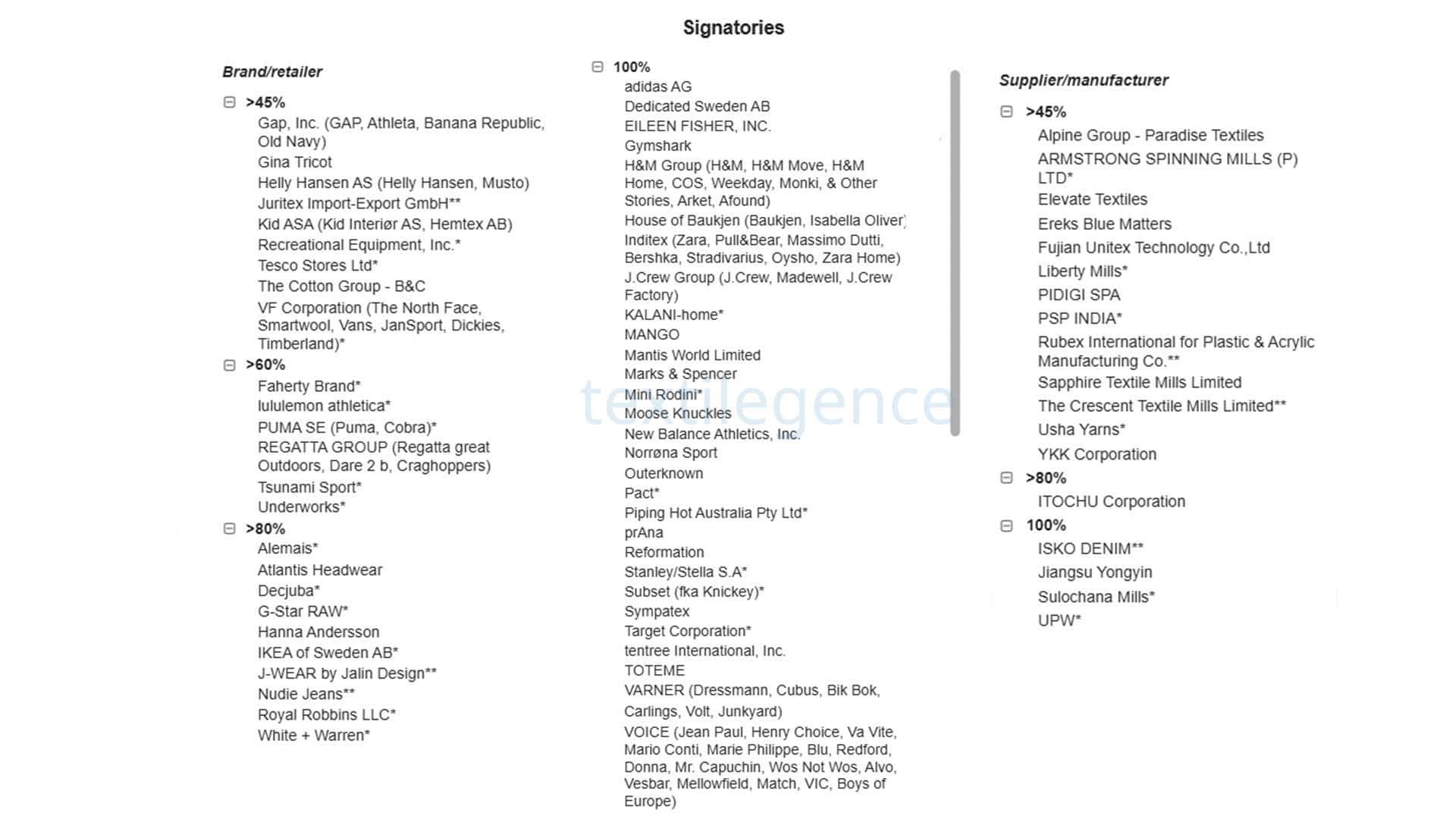

The number of the Recycled Polyester Challenge signatories (brands and suppliers) in 2024 is 121 and brands and suppliers that have already reached their target in 2023 are 28%. While 57% of the signatories committed to replacing 100% of their virgin fossil-based polyester with recycled by 2025, the approximate share of the total apparel polyester market covered by the brands and retailers signatories is 2.6%.

Conventional polyester is made from fossil fuel-based chemicals, the primary raw material of which is crude oil. The commercial production of conventional polyester requires ethylene and ethylene glycol, as well as para-xylene, which is used to produce terephthalic acid (TPA). Together these chemicals produce polyethylene terephthalate, or PET.

57% of the signatories committed to switching to 100% recycled polyester by 2025

Polyester is the most popular material used in the fashion and textile industry. This reliance on virgin fossil-based materials is damaging to the environment, but there’s no other fiber on the market today that could absorb this demand. That’s why Textile Exchange is challenging the fashion and textile industry to increase the market share of polyester that comes from recycled sources from 14% in 2019 to 45% in 2025.

Sugar cane can be an alternative to virgin polyester

Post-consumer recycled bottles are commonly used to produce recycled polyester today, but for closing the loop and creating in-sector circularity, their production is not encouraged much. Instead, companies are incentivised to invest the solutions such as textile-to-textile recycling by partnering with recyclers and other links in the supply chain. In addition, biobased polyester, produced using renewable raw materials such as sugar cane, is a promising alternative, but it’s still in development. Investing in research to help bring new materials to market is essential to reduce dependence on virgin polyester.

Furthermore, Textile Exchange highlights the importance of storytelling, through which companies can raise awareness of the dangers of plastic among consumers by promoting the recycling polyester. Thus, by driving demand for recycled materials, it is stated that brands can make a stronger business case for investing in recycled inputs.